#Overview

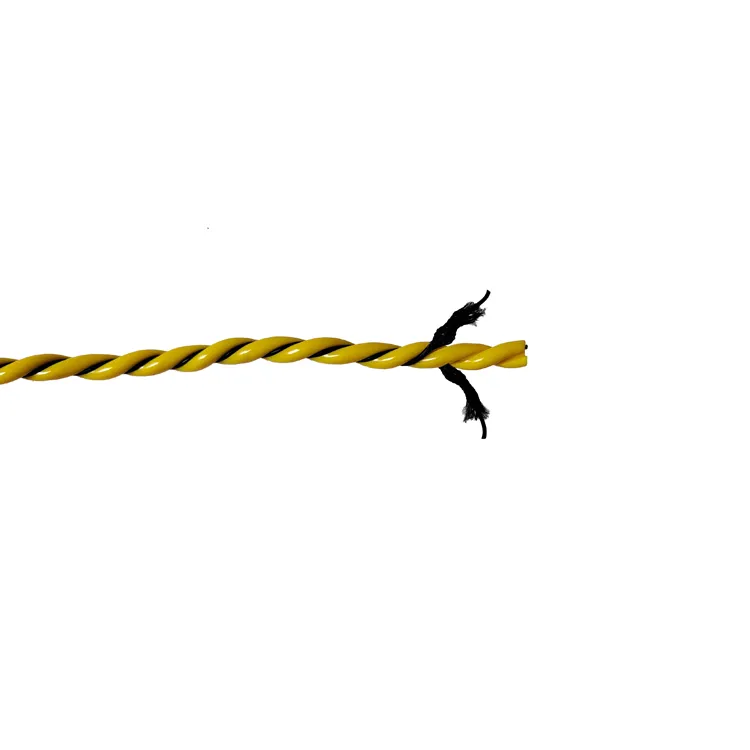

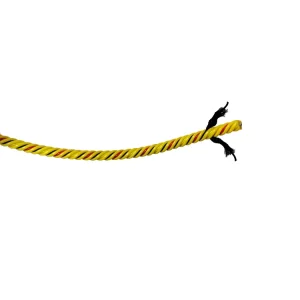

The EX-LS-W2S solves common reliability issues by combining a robust nylon sheath with a flexible spiral core and HDPE-jacketed conductors. This design specifically addresses both moisture absorption and physical shorts, the primary causes of false alarms in real-world installations.

#Key Features

- Dual False Alarm Protection: The nylon braid prevents ambient humidity from triggering alarms. Its abrasion-resistant braid physically isolates the internal conductors, preventing shorts from contact with grounded metal surfaces.

- Spiral Structure: Provides inherent flexibility and strength for easy deployment in complex routes.

- Industrial-Grade Durability: Offers significantly longer service life than the standard cable without nylon braid sheath in demanding conditions.

- Wide Compatibility: Works with most standard non-locating leak controllers.

#Technical Specifications

- Model: EX-LS-W2S

- Type: 2-Wire, Non-Locating

- Cable Diameter: φ6.0mm

- Max Operating Temperature: 75 °C

- Conductor Outer Jacket Material: Nylon Braided Sheath

- Compatibility: Non-Locating Leak Controllers

#FAQ

-

Q: How does it prevent false alarms from metal contact?

A: The tough nylon braid acts as a sacrificial insulating layer, preventing the internal HDPE-jacketed conductors from being exposed and shorting out if the cable is pressed against or abraded by metal structures. -

Q: Is it worth the upgrade from the EX-LS-W2?

A: If your installation environment has high humidity, condensation, or the cable may contact metal (e.g., under raised floors), then the EX-LS-W2S is a necessary upgrade to ensure system reliability and avoid nuisance alarms.