#Overview

Our clamp-on ultrasonic transducers offer the ultimate solution for non-invasive flow monitoring. Simply mount them externally on the pipe, and they will accurately measure flow rate through the pipe wall. This eliminates pressure loss, risk of leakage, and costly downtime for installation. This series covers an exceptionally wide range of pipe sizes, making it perfect for system audits, temporary measurements, or permanent installations where intrusion is not an option.

#Key Features

- True Non-Intrusive Measurement: No need to cut pipes or stop the flow, saving time and money.

- Wide Pipe Diameter Range: Covers applications from small DN10 lines to large DN4000 conduits.

- Versatile Mounting: Suitable for a variety of pipe materials including steel, copper, PVC, and more.

- No Pressure Drop: Since nothing protrudes into the flow, there is zero pressure loss.

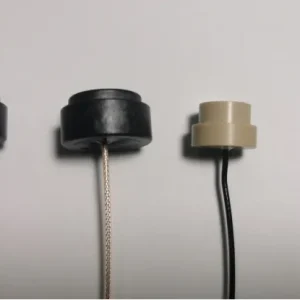

- Pre-Angled Housing: The incident angle is pre-set for common pipe materials (like CPVC, PEL) for easy installation.

#Technical Specifications

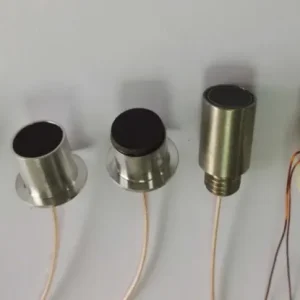

| Part number | SUS0500K50TR | SUS1000K25TR | SUS2000K16TR |

| Norminal Frequency | 500KHz | 1MHz | 2MHz |

| Construction | High frequency type | High frequency type | High frequency type |

| Using Method | Dual Use | Dual Use | Dual Use |

| Bandwidth | ±25KHz | ±50KHz | ±100KHz |

| Overall Sensitivity (0dB=20Vp-p,9 Pulse) |

-45dBmin | -45dBmin | -45dBmin |

| Ring(μs) | 60max | 35max | 25max |

| The Incident Angle | 39º(PEI) | 35º(CPVC) | 35º(CPVC) |

| Free Capacitance (1 KHz) |

4000Pf±20% | 1800Pf±20% | 1200Pf±20% |

| Max. Driving Voltage | 500Vp-p | 300Vp-p | 200Vp-p |

| Directivity Beamwidth | 6º | 7º | 5º |

| Suitable Diameter | DN200~DN4000 | DN32~DN400 | DN10~DN100 |

| Operating temperature range | -20℃ to +80℃ | -20℃ to +80℃ | -20℃ to +80℃ |

| Storage temperature range | -20℃ to +80℃ | -20℃ to +80℃ | -20℃ to +80℃ |

| The Standard Cable Length | 10m | 5m | 5m |

| Housing material | PVC/ Aluminum | PVC/ Aluminum | PVC/ Aluminum |

#FAQ

-

Q: What pipes can these be used on?

A: They work on most common pipe materials that transmit ultrasonic energy, such as steel, stainless steel, copper, CPVC, and PVC. They are not suitable for lined concrete or cast iron pipes. -

Q: Why are there different frequencies for different pipe sizes?

A: Lower frequencies (like 500KHz) penetrate thicker pipe walls and are better for larger pipes or those with linings. Higher frequencies (like 2MHz) provide better resolution for smaller, thinner-walled pipes. -

Q: Can the incident angle be customized?

A: Yes, we can customize the incident angle upon request to match specific pipe materials and wall thicknesses.